We have:

±2,500㎡ Dongguan smart manufacturing base

Singapore overseas operations center

North American representative office

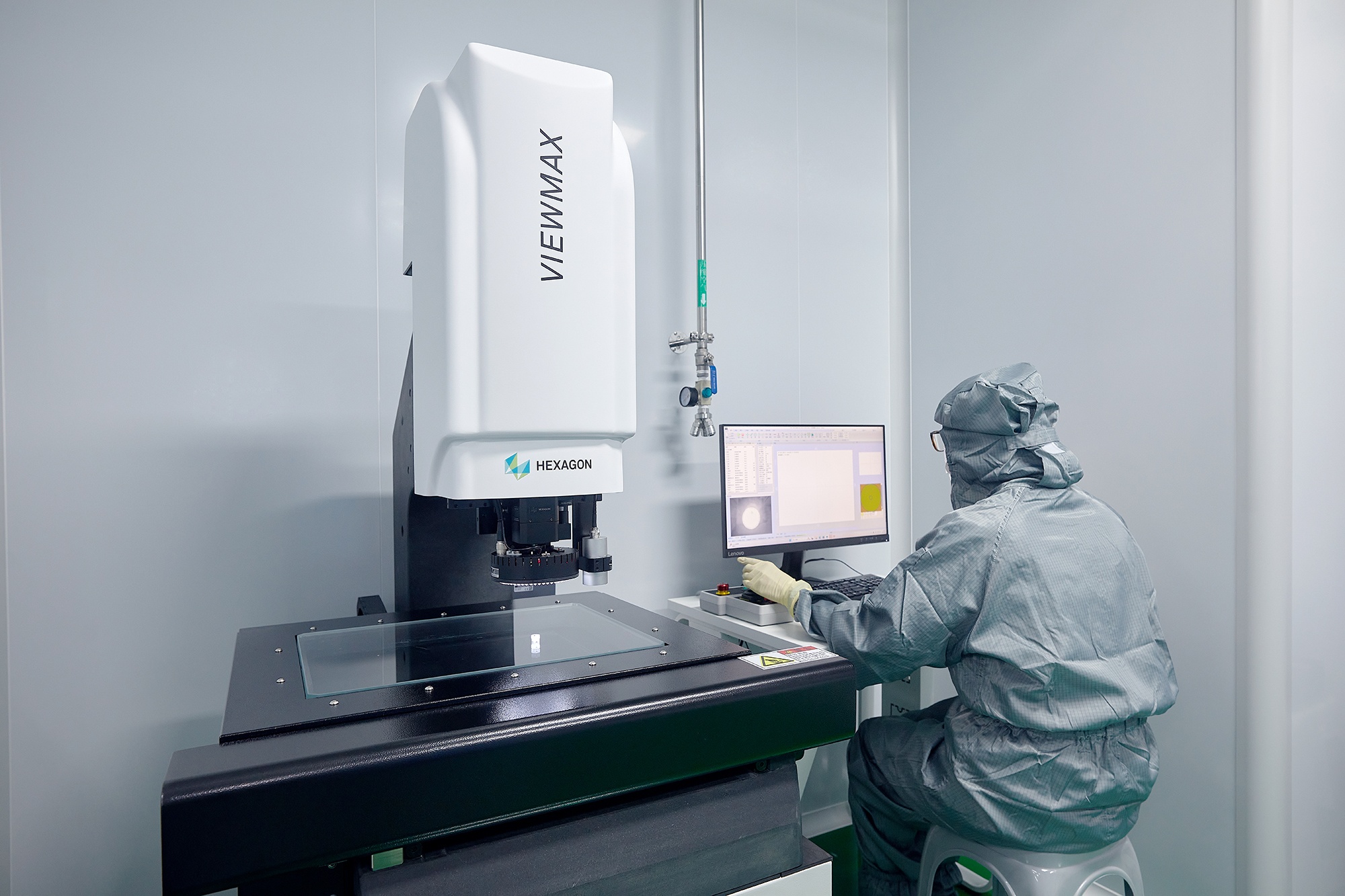

Core Production Technologies

Precision Injection Molding

• Sodick all-electric machines (450T/300T/200T/100T)

• ±0.01mm tolerance, cleanroom-compatible

• MES system integrated

Medical-Grade Extrusion

• 316L stainless steel systems

• 0.22mm±0.01mm micro-tubing production

• pH1-14 chemical resistance

SMT

• Full SMT line (CHM551 pick-and-place)

• 8-zone reflow oven

• Medical PCBA specialization

Advanced Welding

• Laser welding for precision joints

• Ultrasonic welding for cleanroom applications

Specializations

• CAR-T cell therapy equipment

• Microfluidic module design

Taking responsibility

Showing respect to others

Being skilled at our jobs

Believing in what we do

Delivering what we promise

Always looking for a better way

Not blindly doing what we are told

Being open and honest

Always follow your heart

Stay loyal to clients

Maintaining a positive outlook

Keeping balance in our lives

Playing a little every day