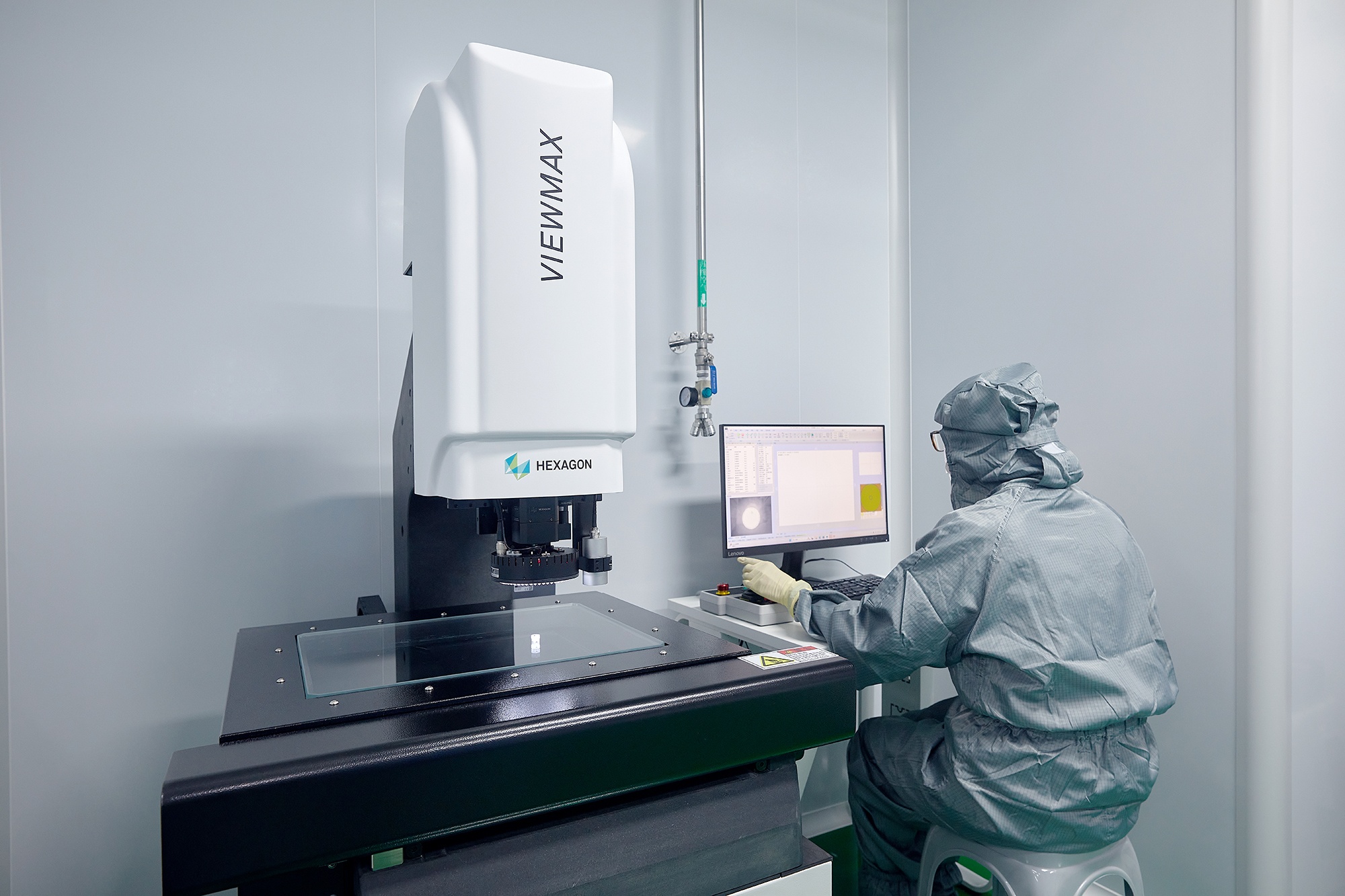

Sampling ratios are set according to AQL standards. All incoming materials must pass inspection before being stored in inventory.

We have a dedicated team of professional Quality Engineers (QEs) focused on analyzing and resolving quality issues. They respond quickly to anomalies, lead root cause investigations, implement corrective and preventive actions, and are committed to continuously improving product quality and customer satisfaction.

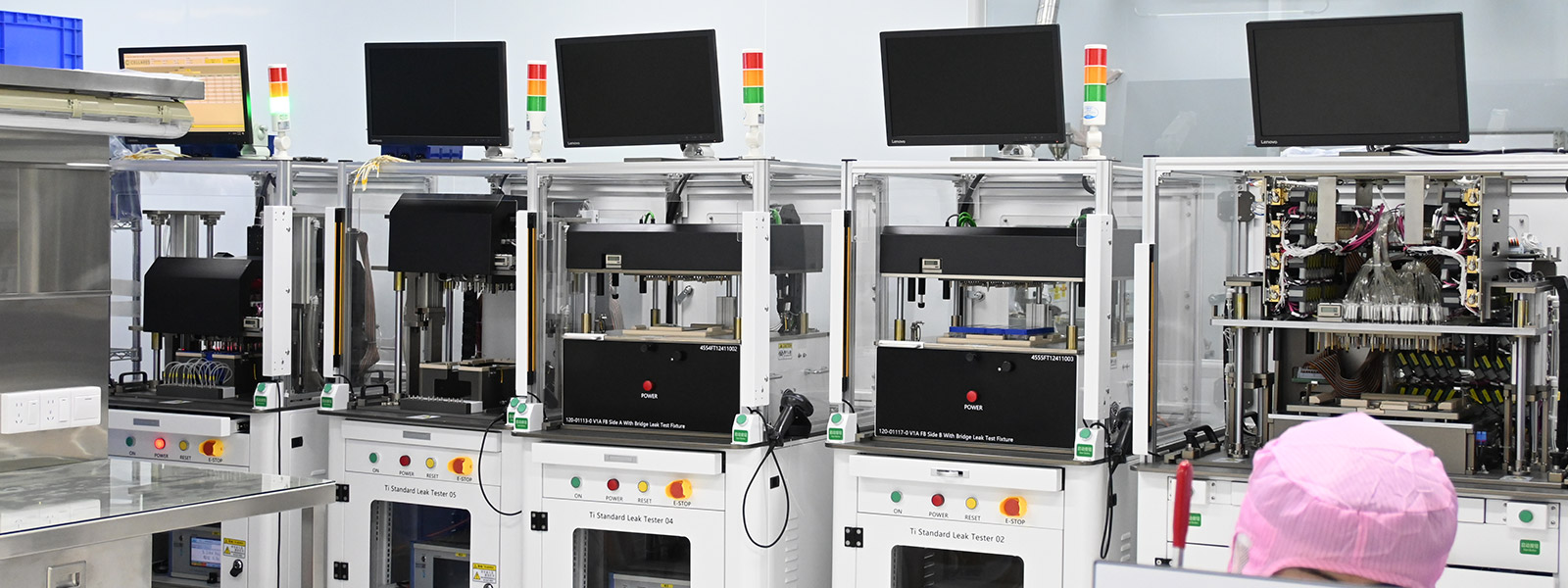

In the medical device industry, airtightness and unobstructed flow path are directly linked to product safety, functional stability, and even patient lives. Therefore, the precision and adaptability of testing equipment are critically important.

At Kingsin, we specialize in the design and manufacturing of customized leak test systems that can handle complex structures and a high number of connection interfaces with precision and reliability. Most currently available test systems on the market lack both reliability and efficiency.

This system is specifically designed to perform comprehensive sealing and flow performance validation across a wide range of application scenarios.